Test program

Currently, the design for structural vibration induced by human walking is based on the walking forces obtained on rigid surfaces. It is largely unknown how footstep forces would be modified if the surfaces are vibrating, especially when the step frequency is near the natural frequency of pedestrian structures (e.g., footbridges). The proposed tests aim to reveal the interaction mechanism between pedestrians and vibrating structures by combining testing and analysis techniques from human motion science and structural engineering. The tests consist of two test series: Phase I and Phase II. In particular, Phase I will be mainly conducted on VSimulators (VSim) motion platform facility and Phase II will be carried out on Exeter bridge (a FRP footbridge located at Exeter Science Park). The present test plan is developed for Phase I at VSim.

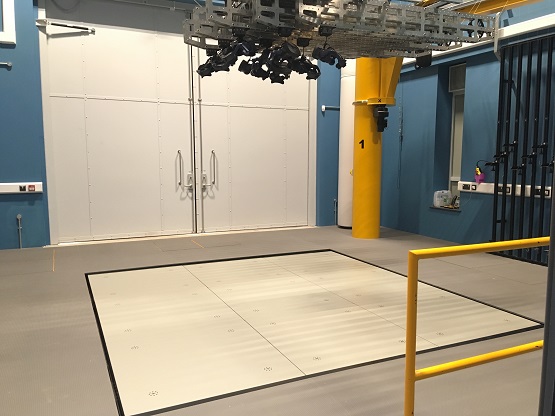

A group of 12 healthy participants (6 male and 6 female) will be recruited in this study from students and staff in the University of Exeter. During pre-test visit, their physical data (e.g., body mass, height, leg length) will be measured as well as walking speeds. During Phase I tests, participants will be asked to walk on a treadmill placed on the VSim platform at their selected walking speeds (see Figure below). The platform will oscillate with different combination of frequency, amplitude and duration. Metabolic cost, kinematic data and ground reaction force (GRF) will be recorded.

Phase II tests will be conducted on the Exeter Footbridge outside of the VSim building (see Figure below). A pair of insole pressure sensors will be put in the shoes to measure the GRF.

The study was approved by College of Engineering Mathematics and Physical Sciences Ethics Committee.